Food-grade χειρισμός κονιαμάτων και χύδην στερεών για παραγωγή τροφίμων

Ο χειρισμός κονιαμάτων και χύδην στερεών σε διεργασίες επεξεργασίας και παραγωγής τροφίμων απαιτεί ειδικό εξοπλισμό. Στην Ευρώπη, αυτό σημαίνει εξοπλισμό που συμμορφώνεται με τον [Κανονισμό (ΕΚ) αριθ. 1935/2004] (https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32004R1935) για υλικά και αντικείμενα τα οποία προορίζονται να έρθουν σε επαφή με τρόφιμα.

Food-grade φλαντζωτά κυλινδρικά φίλτρα αποκονίωσης

EC 1935/2004 compliant dust filtration technology for food processing

The WAMFLO Food Dust Collector range is the result of WAM’s decades of experience in dust filtration technology in food processing in particular.

WAMFLO Food FN200 and FN200X are cutting edge products specially designed to meet the requirements of the industry. With its zero dust residue design WAMFLO Food, in fact, complies with the EC 1935/2004 directive and is suitable for a variety of applications in food processing (wheat, beans, sugar, rice, coffee, cocoa, diet foods, chilli pepper, etc.).

WAMFLO Food FN200 Dust Collectors are equipped with a cylindrically shaped stainless steel casing and welded flanged bottom ring which contains vertically mounted filter bag elements of various types of fabrics which are all food-grade and certified.

An air jet filter element cleaning system is integrated in the hinged top cover. WAMFLO Food FN200 Dust Collectors are available with or without suction fan. As an option for applications with top-mounted suction fan or in case of limited headroom, WAMFLO Food FN200 can be equipped with a newly designed inspection door fitted on the casing with an innovative captive twist lock system which facilitates safe access to the filter elements for inspection or maintenance. WAMFLO Food FN200 is supplied with an integrated modular electronic panel able to manage cleaning cycles according to the specific requirements of the work process. The FN200X model is suitable for operation in explosive environments.

Food-grade ανοιξείδωτοι κοχλίες μεταφοράς

Traceability of all manufactured components and materials is ensured by certification according to European Regulation (EC) No. 1935/2004.

The TXF Stainless Steel Tubular Screw Conveyor series is the state-of-the-art solution for the food industry. They are suitable for applications in which any contamination of the material handled has to be strictly avoided and where absolute cleanliness and perfect resistance to corrosion are required.

TXF Tubular Screw Conveyors and Feeders have been specially designed to meet the requirements of the food industry. Manufactured from stainless steel, this screw conveyor line offers a high grade of surface finishing. Manufacture of fabricated components is carried out on machines that guarantee a perfectly smooth surface which is why material residue is reduced to the minimum.

TXF Tubular Screw Conveyors and Feeders are made up of a tubular trough equipped with inlet and outlet spout, an end plate at each tube end, helicoid screw flighting continuously welded on a centre pipe with drive shaft coupling bush, a drive end bearing assembly complete with air or gas-purged shaft seal, as well as a tube cover plate complete with screw fixing quick pin coupling locator for support of the screw at the end opposite the drive unit. Furthermore, TXF Screws are equipped with a gear motor appropriate for the application.

TXF Screw Conveyors and Feeders are optionally available with ATEX, Zone 22 or Zone 21 certification.

Food-grade βαλβίδες τύπου πεταλούδας (butterfly valve)

EC 1935/2004-compliant material interception beneath hoppers, bins, silos, screw or other type conveyors, or pneumatic conveying ducts.

VFP Butterfly Valves consist of two high-pressure die-cast semi-bodies manufactured from aluminium alloy, a swivel disc in SINT engineering polymer, stainless steelor cast iron, and a pre-stressed elastomeric seal.

VFP Butterfly Valves are used in all types of bulk solids processing plants where interception of gravity-fed or pneumatically conveyed dry powders or granules is required. VFP Butterfly Valves can be fitted beneath hoppers, bins, silos, screw or other type conveyors, or for material interception in pneumatic conveying ducts. Due to their special design and to the engineering materials used, they represent a particularly economic yet most efficient solution in all product processing where contamination and material pollution represent a critical point.

For food applications, a version with stainless steel disc and integral FDA-approved seal is available.

Food-grade βαλβίδες τύπου θυρίδας, χαμηλού προφίλ

Reliable, versatile, and durable in use with powdery or granular materials.

The wide use of WAM’s special SINT engineering polymer and an innovative design geometry make these Low Profile aluminium Slides Valves the ideal solution for intercepting the flow of powders, flakes or granular materials in gravity or conveying applications. A food-grade version in compliance with Regulation (EC) No. 1935/2004 matches requirements from the high end of the industry.

The low-profile VIB Slide Valves consist of two high pressure die-cast semi-bodies manufactured from aluminium alloy, a sliding blade in carbon or stainless steel, a carbon or stainless steel frame and a pre-stressed elastomeric seal manufactured from WAM’s unique SINT engineering polymer composite.

The use of SINT engineering polymer composites considerably increases resistance to abrasion as compared to traditional valves. The valves are equipped with live-loaded seals which ensure extended durability and wear resistance, providing excellent sealing across the entire valve surface. Additional flange gaskets are not required.

VIB Slide Valves are available in a variety of configurations: the VIBQ version comes with a square inlet; the VIBC-type has a circular open cross section.

For the food industry a version with stainless steel blade and frame, as well as food-grade seal is available.

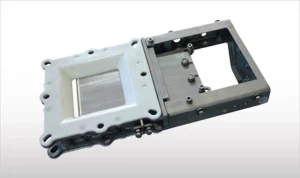

Food-grade ενεργοποιητές κάδου

Hygienic design and finishing, compliance with the EC 1935/2004 directive.

The BAF by EXTRAC is the ultimate Bin Activator specifically designed to meet the requirements of the food industry. With its hygienic design and finishing, it complies with the EC 1935/2004 directive and is suitable for a variety of applications in food processing.

The BAF Bin Activator for Food Applications is a device of tapered conical shape that, due to vibration, facilitates material flow from hoppers or silos during discharge.

Manufactured from stainless steel, the BAF Bin Activator line offers a high surface finishing grade. The mating parts are continuously welded on both sides, deburred and smoothened on the edges, niches, cracks, and crevices, thus obtaining a perfectly smooth surface. As a result, material residue is reduced to the minimum.

BAF Bin Activators consist of a seamless 304L or 316L stainless steel cone manufactured on a sheet metal lathe, a seamless gasket with integrated upper and lower flanges manufactured from food-grade SINTAL engineering polymer, suspensions connecting the Activator with the silo cone, as well as one or two electric motovibrators by OLI.

The BAF Bin Activator for Food Applications is the ideal choice in terms of quality, assurance and reliability for applications requiring safety and consistent material discharge.

It has been specifically designed to work in applications where minimum material residue is required and contamination has to be strictly avoided.

Traceability of all parts of the Bin Activator in contact with the material is ensured by certification according to (EC) No.1935/2004.

Food-grade βαλβίδες εκτόνωσης πίεσης σιλό

Even though ideally a Pressure Relief Valve should never have to go into action, it must be efficient and reliable if needed.

VCP Pressure Relief Valves consist of a cylindrical casing with a bottom flange to be connected with a spigot welded on the silo roof, a disc shape inner steel lid for negative pressure operation held in position by a central spring rod, an outside steel ring for excess pressure kept in position by three spring rods, gaskets, and a weather protection cover.

Helical springs keep the valve lids closed when the pressure value remains within the preset limits. The three outside spring rods keep the external ring-shaped lid firmly closed as long as the force generated by the pressure inside the silo does not overcome the spring force. Once the pressure exceeds the pre-set value the lid is pushed up and pressure can escape. The smaller lid covers the central circular opening of the external lid from below. It is held in the middle by a single spring rod and is pressed onto the external lid by the normal air pressure inside the silo.

In the event of suction pressure the spring is compressed and allows the lid to drop. The air entering the silo from outside ensures rapid pressure balance and pushes the central lid back up into "closed" position.

For applications in the food industry a version compliant with European Regulation (EC) No. 1935/2004 is available.