Flow interception of powders and bulk solids

In production plants, powders and bulk solids flow, are transported, or conveyed, or dropped from machine to machine, from machine to silos/hoppers/bins, or vice versa. Rarely, however, does this happen non-stop and without batching or diverting material along the process chain.

Mechanical process engineering equipment by WAMGROUP makes it possible to intercept such flow/movement of bulk solids.

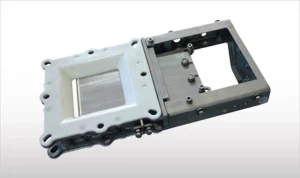

Slide valves / slide gates

Reliable, versatile, and durable in use with powdery or granular materials.

The increased use of WAM’s special SINT engineering polymer in designing the VL range makes these Slides Valves the ideal equipment for intercepting the flow of powdery or granular materials in gravity or conveying applications.

VL-type Slide Valves consist of a two-piece carbon or stainless steel frame partly coated with WAM’s SINT engineering polymer composite, as well as a sliding blade manufactured from SINT engineering polymer, carbon steel or stainless steel. The use of the unique SINT engineering polymer composites considerably increases resistance to abrasion as compared to traditional valves. Moreover, it avoids the use of flange gaskets.

VL Slide Valves are available in a variety of configurations including rectangular sizes. In the VLQ version the valves come with a square, in the VLC version with a circular open cross section, whereas in the VLR-version it is rectangular. The VLS version with square cross section has a pneumatic actuator integrated in its frame.

VL Slides Valves are used where flow of a powdery or granular material caused by gravity or conveying has to be intercepted. Slide valves may be fitted on a hopper or silo outlet, on inlets and outlets of mechanical conveyors, as well as on the inlet of telescopic loading spouts. For conveyor outlets in particular, the VLS version with integrated pneumatic actuator is a valid option due to its compact overall dimensions.

The special geometry of VL Slide Valves and the various options in blade design enable their application in virtually all industries including food processing.

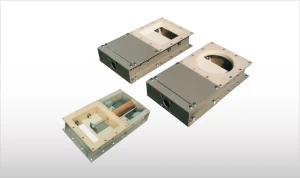

Low-profile slide valves / slide gates

Reliable, versatile, and durable in use with powdery or granular materials.

The wide use of WAM’s special SINT engineering polymer and an innovative design geometry make these Low Profile aluminium Slides Valves the ideal solution for intercepting the flow of powders, flakes or granular materials in gravity or conveying applications. A food-grade version in compliance with Regulation (EC) No. 1935/2004 matches requirements from the high end of the industry.

The low-profile VIB Slide Valves consist of two high pressure die-cast semi-bodies manufactured from aluminium alloy, a sliding blade in carbon or stainless steel, a carbon or stainless steel frame and a pre-stressed elastomeric seal manufactured from WAM’s unique SINT engineering polymer composite.

The use of SINT engineering polymer composites considerably increases resistance to abrasion as compared to traditional valves. The valves are equipped with live-loaded seals which ensure extended durability and wear resistance, providing excellent sealing across the entire valve surface. Additional flange gaskets are not required.

VIB Slide Valves are available in a variety of configurations: the VIBQ version comes with a square inlet; the VIBC-type has a circular open cross section.

For the food industry a version with stainless steel blade and frame, as well as food-grade seal is available.

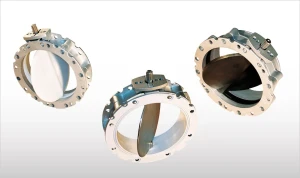

Butterfly valves

VFS represents WAMGROUP's supremacy in bulk solids flow intercepting technology.

VFS Butterfly Valves consist of two high-pressure aluminium alloy die-cast semi-bodies, a SINT polymer composite or cast iron swivel disc, and a pre-stressed elastomer seal. For the food industry a version with stainless steel disc and an FDA/EN-approved, integral seal is available.

While V1FS has a top flange and beaded bottom section – suitable for the attachment of a flexible sleeve – V2FS comes with identical top and bottom flange.

To close silos, hoppers or bins containing powders or granules, VFS Butterfly Valves range among the most widely used equipment worldwide.

What used to be custom-built items for specific applications, WAM has turned into a mass-produced, industrial product with features that allow extremely versatile use.

VFS Butterfly Valves are used in all types of powder and granular material processing plants where interception of gravity-fed or pneumatically conveyed dry materials is required. They are fitted beneath hoppers, bins, silos, screw or other type conveyors, or to intercept pneumatic conveying ducts. Due to their special design and engineering materials used, they represent a particularly cost-effective yet most efficient solution.

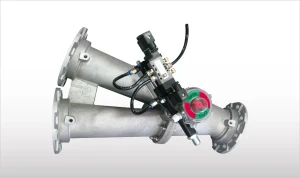

Diverter valves for pneumatic conveying lines

Diverter valves with excellent price-performance ratio.

VAD Diverter Valves consist of an aluminium die-cast casing and a swivel flap that closes one duct or the other. Internal sealing of the body is achieved through low friction gaskets.

Specific surface treatment is available to make the valves suitable for operation with different materials.

VAD-type Diverter Valves are suitable for use in pneumatic conveying lines for handling any type of material in powdery or granular form.

Through activation of the actuator direction of the material flow is changed. VAD-type Diverter Valves guarantee minimum pressure loss and contamination-free, pressure-proof operation.

Flap diverter valves for pneumatic conveying lines

Fitted on pneumatic conveying ducts in which switching the flow of material to different production lines is required.

The VAB Flap Diverter Valve uses a swinging flap to divert material from one duct to another. It is designed to meet the requirement of pneumatic conveying plants in re-routing powders, pellets or granules from one discharge point to another, with minimum pressure drop and high sealing efficiency.

Lump-breaking feeder valves

Safe and smooth segregation of bulk materials that tend to pack and form lumps during production and/or storage.

The design of the LBC Lump-Breaking Feeder Valve favors gentle crushing even with hardened material under a medium-high material column.

The device consists of a solid cylindrical body with inlet and outlet flange, an integrated crushing tool driven by a side-located electric motor and a rigid grid. To adjust to the required particle size both blades and grid are easily removable to be adapted according to the desired material characteristics,

The Lump Breaking Feeder Valve is fed with agglomerated solids which, after being crushed are discharged through the outlet towards further processing. The LBC is the ideal solution to break up snow-ball-like materials. It is particularly suitable for hygroscopic materials and those that are compacted under pressure, such as sugar, salt, silicates, chemicals, and food products in general. The LBC Lump Breaking Feeder Valve can be fitted in loading and/or discharging pipes, for emptying or filling drums, bins, or screw conveyors.

Aerator pads

Trouble-free material flow from silos, bins or hoppers with a variety of powdery materials.

I100 Aerator Pads are a low-cost solution which ensures trouble-free material flow from silos, bins or hoppers with a variety of powdery materials. They can be easily mounted and retrofitted in existing plants.

Due to the semi-convex shape of the durable polymer pad, air is given off with a wide emission angle across the entire white filter surface.

Low pressure aeration or fluidisation prevents rat-holing, bridging, segregation or material residues at the bottom of the silo cone.

I100 Aerator Pads excel thanks to a lightweight, yet robust and reliable engineering polymer casing and filter design. In a single row installation, they are widely used for materials such as cement and similar materials. More sophisticated applications with alternately-fed multiple rows can be used for lime storage and dosing plants in which fluidisation is used not only during discharging of the silo but also to keep the material in motion during extended periods of storage.

A rectangular, external mounting kit is available for easily fitting or retrofitting batching plants.

Air hammers

GUNJET PG Air Cannons (blasters) are successfully used where bridging or rat-holing occurs.

They are ideal for setting in motion irregularly shaped, dry and light bulk solids (e.g. fibres, shavings, flakes, wood chippings, plastic chippings).

GUNJET PG Air Cannons are designed to inject blasts of high pressure gas at up to 6 bar (87 psi), for a short duration (typically fractions of a second) resulting in bridging or rat-holing material to collapse.

In the standard version GUNJET PG Air Cannons are electro-pneumatically activated. A fully pneumatic version is available on request.

When operating multiple air cannons, those at the bottom should be fired first, moving on progressively upwards at regular intervals.

The curved outlet pipe conveys air tangentially along the wall of the bin or silo.

Its robust design makes the GUNJET PG Air Cannon suitable for both indoor and outdoor installation. The external parts of the body are manufactured from galvanized steel and aluminium.

GUNJET PG Air Cannons are supplied with a mounting plate which has to be welded on the bin/hopper/silo wall. A safety chain prevents accidental dropping during installation or maintenance.

GUNJET PG Air Cannons come in three different sizes.

Rat-holing

Rat-holing is a phenomenon that frequently occurs inside bins or silos with certain materials. Due to the physical and chemical properties of the product, the central material column drops instantaneously as soon as the silo outlet valve is opened, while the surrounding material remains immobile.

Especially with light materials, a PG-type GUNJET Air Cannon is often the ideal solution for such inconvenient situations. Other applications are the corners of rectangular-shaped bins where because of tiled walls or inserts, hammering or vibration on the outlet sections is unsuitable. GUNJET Air Cannons are also successfully used in cases where bridging occurs.